|

|

|

|

|

|

| Illustration 1 | g01424011 |

|

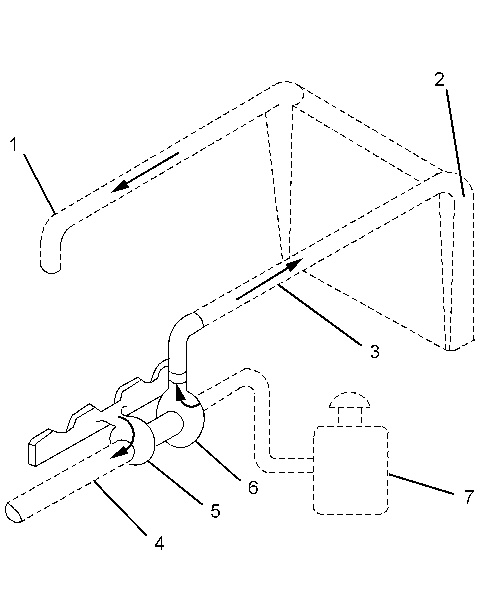

Air inlet and exhaust system schematic (1) Inlet to the engine (2) Aftercooler core (3) Inlet air line (4) Exhaust outlet from turbocharger (5) Turbine side of turbocharger (6) Compressor side of turbocharger (7) Air cleaner |

|

The engine components of the air inlet and exhaust system control the quality of air and the amount of air that is available for combustion. The components of the air inlet and exhaust system are the following components:

- Air cleaner

- Turbocharger

- Aftercooler

- Cylinder head

- Valves and valve system components

- Piston and cylinder

- Exhaust manifold

The turbocharger compressor wheel pulls inlet air through the air cleaner and into the air inlet. The air is compressed and this causes the air to become hot. The air flows through aftercooler core (2) and the temperature of the compressed air lowers. This helps to provide increased horsepower output. Aftercooler core (2) is a separate cooler core that is mounted in front of the engine radiator. The engine fan causes ambient air to move across both cores. This cools the turbocharged inlet air and the engine coolant.

Air is forced from the aftercooler into inlet manifold (1). The air flow from the inlet port into the cylinders is controlled by inlet valves.

|

|

|

|

|

|

| Illustration 2 | g01424012 |

|

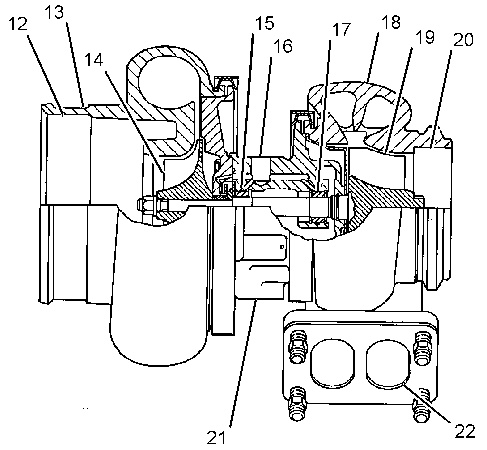

Air inlet and exhaust system (2) Aftercooler core (4) Exhaust outlet (5) Turbine side of turbocharger (6) Compressor side of turbocharger (8) Exhaust manifold (9) Exhaust valve (10) Inlet valve (11) Air inlet |

|

Each cylinder has two inlet valves (10) and two exhaust valves (9) in the cylinder head. The inlet valves open on the inlet stroke. When the inlet valves open, compressed air from the inlet port within the inlet manifold is pushed into the cylinder. The inlet valves close when the piston begins the compression stroke. The air in the cylinder is compressed and the fuel is injected into the cylinder when the piston is near the top of the compression stroke. Combustion begins when the fuel mixes with the air. The force of combustion pushes the piston on the power stroke. The exhaust valves open and the exhaust gases are pushed through the exhaust port into exhaust manifold (8). After the piston finishes the exhaust stroke, the exhaust valves close and the cycle begins again.

Exhaust gases from the exhaust manifold flow into the turbine side of turbocharger (5). The high temperature exhaust gases cause the turbocharger turbine wheel to turn. The turbine wheel is connected to the shaft that drives the compressor wheel. Exhaust gases from the turbocharger pass through exhaust outlet (4), through a muffler, and through an exhaust stack.

Turbocharger

|

|

|

|

|

|

| Illustration 3 | g01804374 |

|

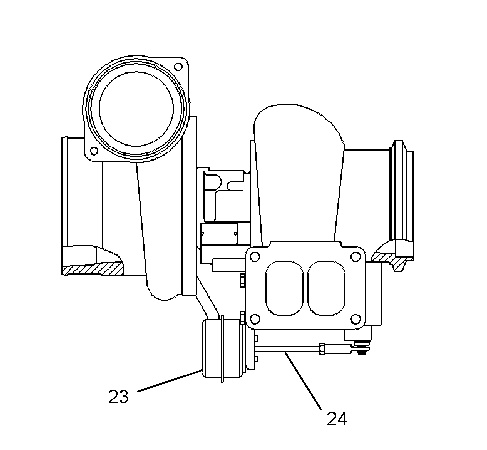

Turbocharger (12) Air inlet (13) Compressor housing (14) Compressor wheel (15) Bearing (16) Oil inlet port (17) Bearing (18) Turbine housing (19) Turbine wheel (20) Exhaust outlet (21) Oil outlet port (22) Exhaust inlet |

|

The turbocharger is mounted to the exhaust manifold of the engine. All of the exhaust gases go from the exhaust manifold through the turbocharger.

The exhaust gases enter the turbocharger and the turbine wheel is turned. Because the turbocharger turbine wheel is connected by a shaft to the turbocharger compressor wheel, the turbine wheel and the compressor wheel turn at very high speeds. The rotation of the compressor wheel pulls clean air through the compressor housing air inlet. The action of the compressor wheel blades causes a compression of the inlet air. This compression allows a larger amount of air to enter the engine. With more air in the engine, the engine is able to burn more fuel. The overall effect is an increase in power.

|

|

|

|

|

|

| Illustration 4 | g01804375 |

|

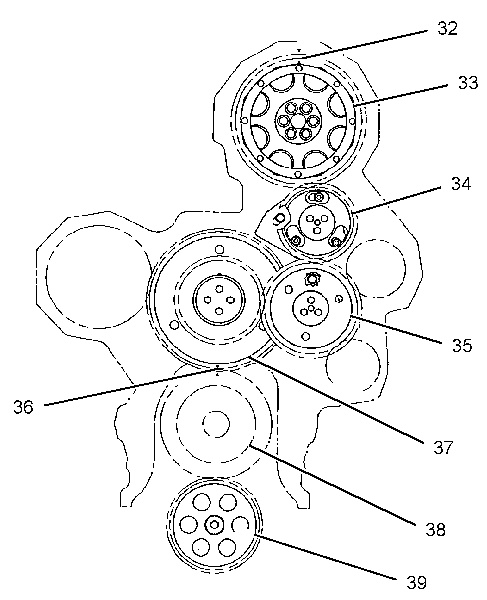

Turbocharger with wastegate (23) Canister (24) Actuating lever |

|

The engine can operate under conditions of low boost. Low boost is a condition that occurs when the turbocharger produces less than optimum boost pressure. There is a spring that is inside canister (23). Under low boost, the spring pushes on the diaphragm in canister (23). This moves actuating lever (24). The actuating lever closes the wastegate, which will allow the turbocharger to operate at maximum performance.

Under conditions of high boost, the wastegate opens. The open wastegate allows exhaust gases to bypass the turbine side of the turbocharger. When the boost pressure increases against the diaphragm in canister (23), the wastegate is opened. The rpm of the turbocharger is limited by bypassing a portion of the exhaust gases around the turbine wheel of the turbocharger.

Note: The calibration of the wastegate is preset at the factory. No adjustment can be made to the wastegate.

Bearing (15) and bearing (17) in the turbocharger use engine oil that is under pressure for lubrication. The lubrication for the bearings flows through oil inlet port (16) and into the inlet port in the center section of the turbocharger cartridge. The oil exits the turbocharger through oil outlet port (21). The oil then returns to the engine oil pan through the oil drain line for the turbocharger.

Valves And Valve Mechanism

|

|

|

|

|

|

| Illustration 5 | g01804414 |

|

Valve system components (25) Valve bridge (26) Rocker arm (27) Camshaft (28) Rotocoil (29) Valve spring (30) Valve guide (31) Valve |

|

The valves and the valve mechanism control the flow of inlet air into the cylinders during engine operation. The valves and the valve mechanism control the flow of exhaust gases out of the cylinders during engine operation.

|

|

|

|

|

|

| Illustration 6 | g01804418 |

|

Components of the gear train (32) Timing mark (33) Camshaft gear (34) Adjustable idler gear (35) Idler gear (36) Timing mark (37) Cluster gear (38) Crankshaft gear (39) Oil pump gear |

|

The inlet valves and the exhaust valves are opened by the valve mechanism. The inlet valves and the exhaust valves are also closed by the valve mechanism. This occurs as the rotation of the crankshaft causes the camshaft to rotate. Camshaft gear (33) is driven by a series of two idler gears (34) and (35). Idler gear (34) is driven by cluster gear (37). Cluster gear (37) is driven by crankshaft gear (38). Timing mark (32) and timing mark (36) are aligned in order to provide the correct relationship between the piston and the valve movement.

The camshaft has three lobes for each cylinder. One lobe operates the inlet valves. A second lobe operates the exhaust valves. The third lobe operates the unit injector mechanism. The camshaft lobes turn and the rocker arms move. Movement of the rocker arms will make the inlet and exhaust valve bridges move. These bridges allow one rocker arm to actuate two valves at the same time. Each cylinder has two inlet valves and two exhaust valves. Each valve has one valve spring (29). The spring closes the valve.

Rotocoils (28) cause the valves to rotate while the engine is running. Valve rotation provides a longer service life. Valve rotation also minimizes carbon deposits on the valves.

Adjustable idler gear (34) is designed to provide the required gear backlash between nonadjustable idler gear (35) and camshaft gear (33). If the cylinder head is removed, tolerances of the components will change. The components that change are the cylinder head and the head gasket. The adjustable idler gear must be relocated. For information on setting the correct backlash, refer to Testing and Adjusting, “Gear Group (Front) – Time”.

The camshaft drive gear has integral pendulums which act as a vibration damper for the front gear group. These pendulums are designed to counteract the torsional forces from the injector pulses. This eliminates vibration and noise. The engine also runs smoother at all operating speeds.