System Operation Description:

Use this procedure to troubleshoot the system only under the following conditions:

- There is an active diagnostic code or an easily repeated diagnostic code that is associated with the engine speed/timing sensors.

- You have been sent to this test from Troubleshooting, “Troubleshooting without a Diagnostic Code”.

The engine uses two engine speed/timing sensors. The secondary engine speed/timing sensor picks up the camshaft gear and the primary engine speed/timing sensor picks up the crankshaft gear. Both of the engine speed/timing sensors detect the reference for engine speed and timing from a unique pattern on the respective gear. The Electronic Control Module (ECM) counts the time between pulses that is created by the sensor as the gear rotates in order to determine rpm.

Under normal operation, the secondary engine speed/timing sensor is used to determine timing for starting purposes. The secondary engine speed/timing sensor is used to determine when the piston in the No. 1 cylinder is at the top of the compression stroke. When the timing has been established, the primary engine speed/timing sensor is then used to determine engine speed and the signal from the secondary engine speed/timing sensor is ignored.

After locating the No. 1 cylinder, the ECM triggers each injector in the correct firing order and at the correct unit injector timing. The actual timing and duration of each injection is based on engine rpm and on load. If the engine is running and the signal from the primary engine speed/timing sensor is lost, a slight change in engine performance will be noticed when the ECM performs the changeover to the secondary engine speed/timing sensor. Loss of the signal from the secondary engine speed/timing sensor during engine operation will not result in any noticeable change in engine performance. However, if the signal from the secondary engine speed/timing sensor is not present during start-up the following conditions may exist:

- The engine may require a slightly longer period of time to start-up.

- The engine may run rough for a few seconds until the ECM determines the proper firing order by using the primary engine speed/timing sensor only.

The engine will start and the engine will run when only one sensor signal is present from either of the sensors. The loss of the signal from both of the sensors during engine operation will result in the termination of injection and the shutting down of the engine by the ECM. The loss of the signal from both of the sensors during start-up will prevent the engine from starting.

Both sensors are magnetic sensors with an integral connector. The two sensors are not interchangeable. Do not switch the positions of the sensor. If the sensors are replaced, a timing calibration is not necessary for the engine.

Note: When the sensors are being installed, complete all of the following tasks:

- Lubricate the O-ring with oil.

- Ensure that the sensor is fully seated into the engine before tightening the bracket bolt.

- Ensure that the connector is properly latched.

- Ensure that the harness is properly secured, and ensure that the tie-wraps are placed in the correct location.

|

|

|

|

|

|

| Illustration 1 | g01072831 |

Test Step 1. Check for Diagnostic Codes

- Connect the Caterpillar Electronic Technician (ET) to the service tool connector.

- Turn the keyswitch to the ON position.

- Verify whether any of the following diagnostic codes are active or logged.

- 320-02

- 320-11

- 342-02

- 342-11

- If the diagnostic code is logged but not active, run the engine until the engine is at normal operating temperature. The problem may only occur when the engine is at the normal operating temperature.

- If the engine will not start, monitor the engine speed on Cat ET while the engine is being cranked. Cat ET may need to be powered from another battery while the engine is being cranked in order to ensure that Cat ET does not reset.

Note: Upon initial cranking, the status for engine speed may indicate that the engine speed signal is abnormal. This message will be replaced with an engine speed once the ECM is able to calculate a speed from the signal.

Expected Result:

One or more of the diagnostic codes that are listed above are logged or active.

Results:

- Diagnostic Codes – There is a logged diagnostic code or an active diagnostic code for the engine speed/timing sensors. Proceed to Test Step 3.

- No Diagnostic Codes – There are no diagnostic codes for the engine speed/timing sensors, but the engine is not running properly.

Repair: Proceed to the appropriate topic in Troubleshooting, “Troubleshooting without a Diagnostic Code”.

STOP

- No Engine rpm – Engine rpm is not indicated on Cat ET. Proceed to Test Step 2.

Test Step 2. Check the Installation of the Sensors and the Brackets

|

|

|

|

|

|

| Illustration 2 | g00810795 |

|

Sensors and mounting brackets (typical example) |

|

- The flange of the sensor should be flush against the engine in order to ensure proper operation.

- Inspect the bracket in order to ensure that the installation allows the flange of the sensor to be flush against the engine.

Verify that the bracket is not bent.

Note: The bracket cannot be replaced separately.

- Ensure that the O-ring has been installed on the sensor, and ensure that the O-ring is free of damage.

- If either of the following diagnostic codes is active, there may be a problem with the assembly of the camshaft gear or the crankshaft gear:

- 320-11

- 342-11

Refer to Illustration 2.

Expected Result:

The sensors and the bracket are properly installed.

Results:

- OK – The sensors and the bracket are properly installed. Proceed to Test Step 3.

- Not OK – The sensors and/or the bracket are not properly installed.

Repair: Perform the following procedure in order to properly install the sensors and the bracket:

- Loosen the bolt that holds the sensor mounting bracket to the engine.

- Seat the sensor and tighten the bolt.

If the sensor will not seat, repair the sensor or replace the sensor, as required.

Note: The sensor must not be removed from the bracket.

- Ensure that the sensor is properly oriented and that the harness is secured in the proper location.

- Verify that the repair eliminates the problem.

STOP

Test Step 3. Measure the Sensor Resistance at the ECM Connector

|

|

|

|

|

|

| Illustration 3 | g01055967 |

|

ECM connector P2 |

|

- Turn the keyswitch to the OFF position.

- Thoroughly inspect the J2/P2 ECM connector. Refer to Troubleshooting, “Electrical Connectors – Inspect” for details.

- Perform a 45 N (10 lb) pull test on the following wires in the P2 ECM connector that are associated with the suspect engine speed/timing sensors.

Refer to Illustration 3.

- Ensure that the latch tab on the connector is properly latched and ensure that the latch tab is fully latched.

- Check the ECM connector (allen head screw) for the proper torque. Refer to Troubleshooting, “Electrical Connectors – Inspect” for details.

- Repair the harness or repair the connector if a problem is found.

- Ensure that the wiring harness is correctly routed and secured at the proper locations.

- Ensure that the harness wiring is not pulled too tightly. When the harness wiring is pulled too tightly, vibrations or movement can cause intermittent connections.

- Inspect the harness wiring for nicks and for abrasions.

- If the harness and the connector are okay, disconnect ECM connector J2/P2.

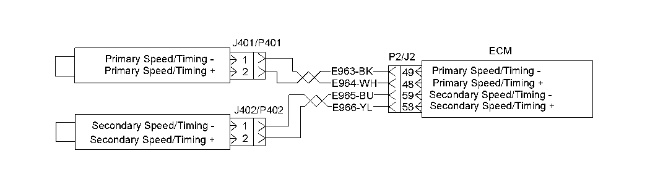

- Use the following procedure to measure the circuit resistance for the primary engine speed/timing sensor:

Refer to Illustration 3.

- Measure the resistance between P2-48 (primary engine speed/timing +) and P2-49 (primary engine speed/timing −).

Note: Check for an intermittent problem (open or short) by moving the harness while you measure the resistance. Pull the wires that are directly behind the sensors and shake the wires that are directly behind the sensors.

Resistance … 75 to 230 Ohms

- Measure the resistance between P2-48 (primary engine speed/timing +) and P2-49 (primary engine speed/timing −).

- Use the following procedure to measure the circuit resistance for the secondary engine speed/timing sensor:

Refer to Illustration 3.

- Measure the resistance between P2:58 (secondary engine speed/timing +) and P2:59 (secondary engine speed/timing −).

Note: Check for an intermittent problem (open or short) by moving the harness while you measure the resistance. Pull the wires that are directly behind the sensors and shake the wires that are directly behind the sensors.

Resistance … 600 to 1800 Ohms

- Measure the resistance between P2:58 (secondary engine speed/timing +) and P2:59 (secondary engine speed/timing −).

Expected Result:

The readings agree with the values that are listed above.

Results:

- OK – Neither a short circuit nor an open circuit is indicated. Proceed to Test Step 7.

- Not OK – The resistance is not within the acceptable range when the circuit resistance is measured through the engine harness. Proceed to Test Step 4.

Test Step 4. Measure the Resistance of the Sensor

- Turn the keyswitch to the OFF position.

- Check the harness and the wiring for abrasion and pinch points from the sensor back to the ECM.

- Disconnect the suspect sensor from the engine harness.

- Thoroughly inspect the connector for the suspect engine speed/timing sensor. Refer to Troubleshooting, “Electrical Connectors – Inspect” for details.

- Use the following procedure to measure the resistance of the primary engine speed/timing sensor:

- Disconnect the J401/P401 primary engine speed/timing sensor connector.

- Measure the resistance between terminal 1 and terminal 2 of the sensor.

Resistance … 75 to 230 Ohms

- Use the following procedure to measure the resistance of the secondary engine speed/timing sensor:

- Disconnect the J402/P402 secondary engine speed/timing sensor connector.

- Measure the resistance between terminal 1 and terminal 2 of the sensor.

Resistance … 600 to 1800 Ohms

Expected Result:

The readings agree with the values that are listed above.

Results:

- OK – The sensor resistance is within tolerance. Proceed to Test Step 5.

- Not OK – The sensor resistance is out of specified range.

Repair: Perform the following procedure in order to check and install the new sensor:

- Before installing the new sensor, measure the resistance of the new sensor.

If the new sensor resistance is in the correct range, install the new sensor in the engine, as follows:

- Loosen the bolt that holds the sensor mounting bracket to the engine.

- Ensure that the O-ring is installed and free of damage.

- Seat the sensor and tighten the bolt.

If the sensor will not seat, repair the sensor or replace the sensor, as required.

Note: The sensor must not be removed from the bracket.

- Ensure that the sensor is properly oriented and that the harness is secured in the proper location.

Note: Timing calibration is not necessary following replacement of the primary engine speed/timing sensor or of the secondary engine speed/timing sensor. Refer to the information in the system operation section regarding the installation of sensors.

- Verify that the repair eliminates the problem.

STOP

- Before installing the new sensor, measure the resistance of the new sensor.

Test Step 5. Check for an Open in the Harness for the Engine Speed/Timing Sensors

- Disconnect ECM connector J2/P2.

- Use the following procedure to check for an open in the wiring for the secondary engine speed/timing sensor at the sensor connector between terminal 1 and terminal 2:

- Install a wire jumper between P2-58 and P2-59 at ECM connector P2.

- Use a multimeter to measure the sensor resistance from P402-1 to P402-2.

Wiggle the harness between the sensor connector and the ECM connector during this procedure.

- Use the following procedure to measure the sensor resistance for the primary engine speed/timing sensor at the sensor connector between terminal 1 and terminal 2:

- Install a wire jumper between P2-48 and P2-49 at ECM connector P2.

- Measure the sensor resistance from P401-1 to P401-2.

Wiggle the harness between the sensor connector and the ECM connector during this procedure.

- Remove all wire jumpers.

Expected Result:

The resistance measures less than 5 Ohms.

Results:

- OK – The resistance measures less than 5 Ohms. Proceed to Test Step 6.

- Not OK – The resistance measures more than 5 Ohms.

Repair: A high resistance indicates an open or partially broken wire. Repair the wire or replace the harness.

STOP

Test Step 6. Check for a Short in the Harness for the Engine Speed/Timing Sensors

- Disconnect ECM connector J2/P2.

- Use the following procedure to check for a short in the wiring for the secondary camshaft position sensor:

- Use a multimeter to measure the resistance from P402-1 to every pin in ECM connector P2 and to engine ground.

Wiggle the harness between the sensor connector and the ECM connector during this procedure.

- Use a multimeter to measure the resistance from P402-2 to every pin in ECM connector P2 and to engine ground.

Wiggle the harness between the sensor connector and the ECM connector during this procedure.

- Use a multimeter to measure the resistance from P402-1 to every pin in ECM connector P2 and to engine ground.

- Use the following procedure to check for a short in the wiring for the primary crankshaft position sensor:

- Measure the resistance from P401-1 to every pin in ECM connector P2 and to engine ground.

Wiggle the harness between the sensor connector and the ECM connector during this procedure.

- Measure the resistance from P401-2 to every pin in ECM connector P2 and to engine ground.

Wiggle the harness between the sensor connector and the ECM connector during this procedure.

- Measure the resistance from P401-1 to every pin in ECM connector P2 and to engine ground.

Expected Result:

The resistance measures more than 20,000 Ohms.

Results:

- OK – The resistance measures more than 20,000 Ohms. Proceed to Test Step 7.

- Not OK – The resistance measures less than 20,000 Ohms.

Repair: A low resistance indicates a short in the wire. Repair the wire or replace the harness.

STOP

Test Step 7. Check the ECM

- Turn the keyswitch to the OFF position.

- Temporarily connect a spare ECM.

- If the problem is resolved with the spare ECM, reconnect the suspect ECM.

- If the problem returns with the suspect ECM, replace the ECM.

Verify that the repair eliminates the problem.

Expected Result:

The problem remains with the suspect ECM.

Results:

- OK – The problem is resolved with the spare ECM and the problem returns with the suspect ECM.

Repair: Replace the ECM.Verify that the repair eliminates the problem.

STOP

- Not OK – The problem was not resolved with a spare ECM.

Repair: Replace the sensor.Verify that the repair eliminates the problem.

STOP