System Operation Description:

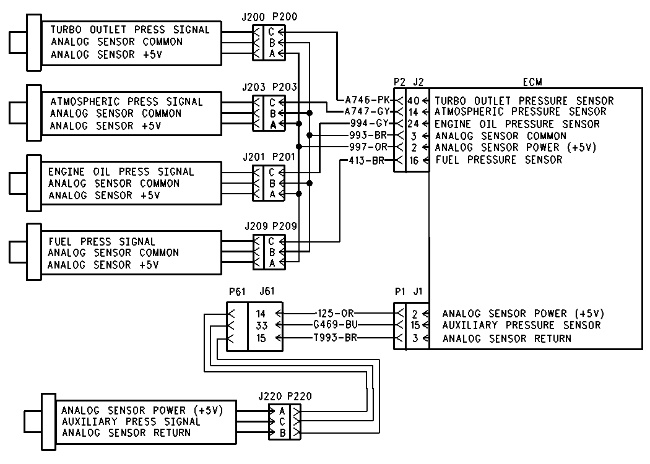

Use this procedure to troubleshoot the system only when there is an active diagnostic code or when a diagnostic code can easily be activated. This procedure covers open circuit diagnostic codes and short circuit diagnostic codes that are associated with the following sensors:

- Atmospheric pressure sensor

- Auxiliary pressure sensor

- Engine oil pressure sensor

- Fuel pressure sensor

- Turbocharger outlet pressure sensor

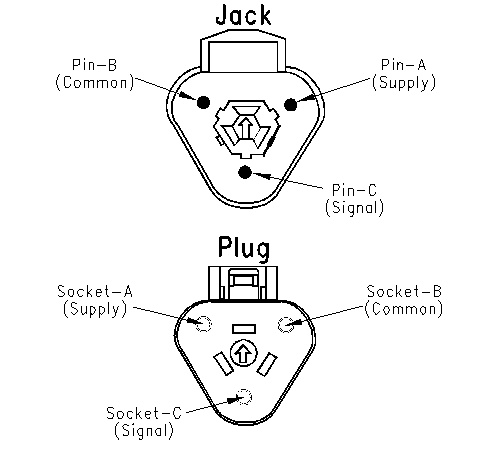

The troubleshooting procedures for the diagnostic codes of each pressure sensor are identical. The Electronic Control Module (ECM) sends a five volt supply to terminal A of each sensor. The sensor common connection is connected to terminal B of each sensor. The signal voltage from terminal C of each sensor is sent to the appropriate terminal on the ECM.

|

|

|

|

|

|

| Illustration 1 | g00750045 |

|

Schematic |

|

|

|

|

|

|

|

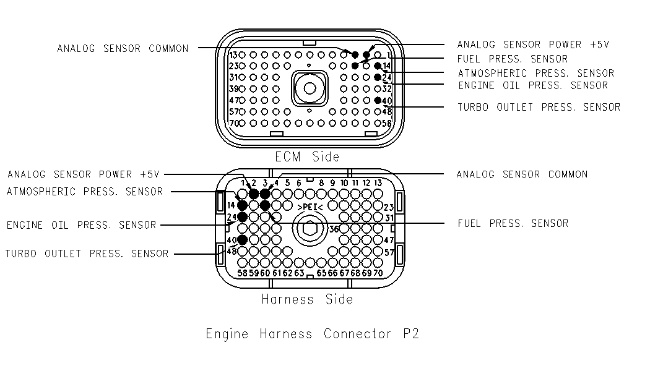

| Illustration 2 | g00763287 |

|

ECM connector J2/P2 |

|

|

|

|

|

|

|

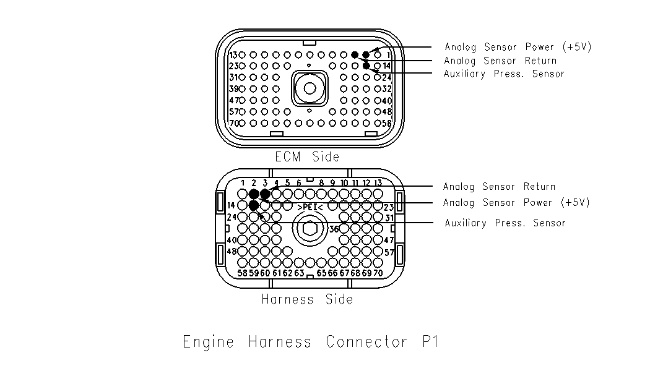

| Illustration 3 | g00763353 |

|

ECM connector J/1P1 |

|

|

|

|

|

|

|

| Illustration 4 | g00810608 |

|

Terminals for pressure sensors |

|

Test Step 1. Check for Active +5 V Sensor Supply Diagnostic Codes

- Connect the Caterpillar Electronic Technician (ET) to the service tool connector.

- Turn the keyswitch to the ON position. Wait at least 15 seconds for activation of the diagnostic codes.

- Verify that neither of the following diagnostic codes are active:

- 262-03 5 Volt Sensor DC Power Supply short to +batt

- 262-04 5 Volt Sensor DC Power Supply short to ground

Expected Result:

Neither of the preceding diagnostic codes are active.

Results:

- OK – The diagnostic codes are not active. Proceed to Test Step 2.

- Not OK – One of the diagnostic codes is active.

Repair: Perform the following diagnostic procedure: Troubleshooting, “5 Volt Engine Pressure Sensor Supply Circuit – Test”.

STOP

Test Step 2. Inspect Electrical Connectors And Wiring

- Thoroughly inspect the J1/P1 ECM connector, the J2/P2 ECM connector, and any connectors that are associated with the suspect pressure sensor. Refer to Troubleshooting, “Electrical Connectors – Inspect” for details.

- Perform a 45 N (10 lb) pull test on each of the wires in the ECM connector and the sensor connectors that are associated with the active diagnostic code.

- Check the ECM connector (allen head screw) for the proper torque. Refer to Troubleshooting, “Electrical Connectors – Inspect” for details.

- Check the harness and wiring for abrasion and for pinch points from the sensors back to the ECM.

Expected Result:

All connectors, pins and sockets are completely coupled and/or inserted and the harness and wiring are free of corrosion, of abrasion, and of pinch points.

Results:

- OK – The connectors and the wiring appear to be OK. Proceed to Test Step 3.

- Not OK – There is a problem with the connectors and/or the wiring.

Repair: Repair the connectors or wiring and/or replace the connectors or wiring. Ensure that all of the seals are properly in place and ensure that the connectors are completely coupled.Verify that the repair eliminates the problem.Clear all logged diagnostic codes.

STOP

Test Step 3. Determine the Condition that is Present

- Turn the key switch to the ON position. Wait at least 15 seconds for activation of the diagnostic codes.

- Monitor the active diagnostic code screen on Cat ET.

- Determine if the problem is related to an open circuit diagnostic code or to a short circuit diagnostic code.

Expected Result:

Either an open circuit diagnostic code or a short circuit diagnostic code is active.

Results:

- Short Circuit – A short circuit diagnostic code is active at this time. Proceed to Test Step 4.

- Open Circuit – An open circuit diagnostic code is active at this time. Proceed to Test Step 7.

Test Step 4. Disconnect the Suspect Sensor

- Turn the keyswitch to the OFF position.

- Disconnect the sensor with the short circuit diagnostic code.

- Turn the keyswitch to the ON position. Wait at least 15 seconds for activation of the diagnostic codes.

- Check for an active open circuit diagnostic code for the disconnected sensor.

Expected Result:

An open circuit diagnostic code is now active for the disconnected sensor.

Results:

- OK – A short circuit diagnostic code was active before disconnecting the sensor. An open circuit diagnostic code became active after disconnecting the sensor.

Repair: Temporarily connect a new sensor.Check for active diagnostic codes.If the new sensor fixes the problem, reconnect the suspect sensor.If the problem returns, permanently install the new sensor.Verify that the repair eliminates the problem.

STOP

- Not OK – There is a short circuit between the sensor and the ECM.

Repair: Leave the suspect sensor disconnected.

Proceed to Test Step 5.

Test Step 5. Create an Open Circuit at the ECM

- Turn the keyswitch to the OFF position.

- Remove the signal wire of the suspect sensor from the appropriate ECM connector.

- Turn the keyswitch to the ON position.

- Check for active diagnostic codes.

Expected Result:

An open circuit diagnostic code became active after removing the signal wire.

Results:

- OK – A short circuit diagnostic code was active before removing the signal wire. An open circuit diagnostic code became active after removing the signal wire. Proceed to Test Step 6.

- Not OK – There is still a short circuit diagnostic code.

Repair: Connect a test ECM.If the test ECM fixes the problem, reconnect the suspect ECM.If the problem returns, permanently replace the suspect ECM.Verify that the repair eliminates the problem.

STOP

Test Step 6. Check the Resistance of the Harness

- Turn the keyswitch to the OFF position.

- Verify that the suspect sensor is disconnected.

- Measure the resistance between terminal B (Common) and terminal C (Signal) of the connector for the suspect sensor on the engine harness.

Expected Result:

The resistance is greater than 20,000 Ohms, or “OL” is displayed on the multimeter.

Results:

- OK – The resistance is greater than 20,000 Ohms, or “OL” is displayed on the multimeter.

Repair: Check the signal wire for a short to ground.Repair the wiring or replace the wiring.Verify that the repair eliminates the problem.

STOP

- Not OK – There is a short between the pressure sensor common and the signal wire.

Repair: Locate the short between the pressure sensor common and the signal wire.Repair the wiring or replace the wiring.Verify that the repair eliminates the problem.

STOP

Test Step 7. Measure the Sensor Supply Voltage

- Turn the key switch to the OFF position.

- Disconnect the suspect sensor.

- Turn the keyswitch to the ON position.

- Measure the voltage from terminal A (+5V) to terminal B (Common).

Expected Result:

The voltage is 5.0 ± 0.16 VDC.

Results:

- OK – The sensor supply voltage is correct.

Repair: Leave the sensor disconnected.

Proceed to Test Step 8.

- Not OK – The sensor supply voltage is out of the range.

Repair: Check the five volt supply wire for an open circuit.Repair the wiring or replace the wiring.Verify that the repair eliminates the problem.

STOP

Test Step 8. Create a Short Circuit at the Sensor

- Turn the keyswitch to the ON position.

- Monitor the active diagnostic code screen.

- Install a jumper wire between terminal C (Signal) and terminal B (Common) of the connector for the suspect sensor on the engine harness. Wait at least 15 seconds for activation of the short circuit diagnostic code.

Expected Result:

A short circuit diagnostic code is active when the jumper wire is installed. An open circuit diagnostic code is active when the jumper wire is removed.

Results:

- OK – The engine harness and the ECM are OK.

Repair: Temporarily connect a new sensor.If the new sensor fixes the problem, reconnect the suspect sensor.If the problem returns, permanently replace the suspect sensor.Verify that the repair eliminates the problem.

STOP

- Not OK – The open circuit diagnostic code remains active when the jumper wire is installed.

Repair: Remove the jumper wire.

Proceed to Test Step 9.

Test Step 9. Create a Short Circuit at the ECM

- Turn the keyswitch to the OFF position.

- Disconnect the ECM connector that is associated with the suspect sensor.

Note: If the suspect sensor is connected to the J1/P1 ECM connector, connect a 140-2266 Cable (Seventy-Pin Breakout) at the J1/P1 ECM connector.

- Turn the keyswitch to the ON position.

- Monitor the active diagnostic code screen. Wait at least 15 seconds for activation of the code.

Note: When the ECM connector is disconnected, all of the open circuit diagnostic codes for the pressure sensors that are wired to that ECM connector will be active. This is normal.

- Install a jumper wire between the terminal for the signal of the suspect sensor and the pressure sensor common on the ECM. If the suspect sensor is connected to the J1/P1 ECM connector, install the jumper at the breakout T. Wait at least 15 seconds for activation of the short circuit diagnostic code.

Expected Result:

A short circuit diagnostic code is active for the suspect sensor.

Results:

- OK – The ECM is operating properly.

Repair: Leave the ECM connector disconnected and/or leave the breakout in place.

Proceed to Test Step 10.

- Not OK – The open circuit diagnostic code is still active when the jumper wire is installed.

Repair: Temporarily connect a test ECM.If the test ECM fixes the problem, reconnect the suspect ECM.If the problem returns, permanently replace the ECM.Verify that the repair eliminates the problem.

STOP

Test Step 10. Check the Resistance of the Harness

- Turn the keyswitch to the OFF position.

- Verify that the suspect sensor is disconnected.

- Check the resistance between terminal A (+5V) and terminal C (Signal) of the connector for the suspect sensor on the engine harness.

Expected Result:

The resistance is greater than 20,000 Ohms or “OL” is displayed on the multimeter.

Results:

- OK – There is an open circuit in the signal wire.

Repair: Locate the open in the signal wire.Repair the wiring or replace the wiring.Reconnect the ECM connector.Verify that the repair eliminates the problem.

STOP

- Not OK – There is a short between the five volt supply and the signal wire.

Repair: Locate the short between the 5 volt supply and the signal wire.Repair the wiring or replace the wiring.Reconnect the ECM connector.Verify that the repair eliminates the problem.

STOP