|

|

|

|

|

|

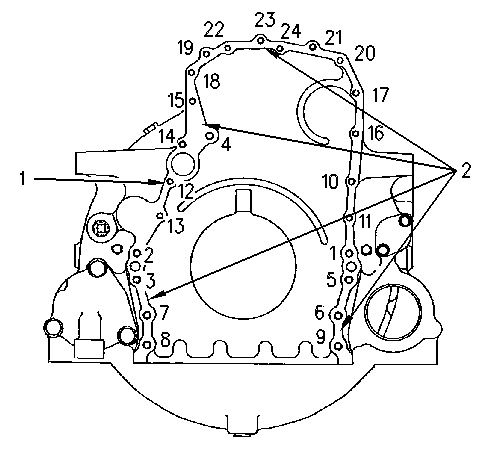

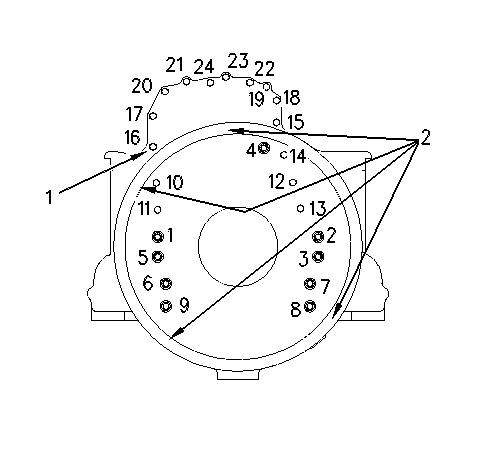

| Illustration 1 | g00383655 |

|

4N-0732 Flywheel Housing |

|

Note: During assembly, inspect the following components for any foreign materials: the front face of the flywheel housing, the two sides of the flywheel housing gasket and the rear face of the cylinder block. These components must be free of the following substances: oil, fuel, water, gasket adhesive, assembly compounds and any other foreign material. After the flywheel housing is installed, cut the gasket even with the pan rail.

(1) To tighten the flywheel housing bolts, use the procedure that follows:

- In a numerical sequence, tighten bolt 1 through bolt 24.

Torque for bolts … 40 ± 10 N·m (3 ± 7 lb ft)

- In a numerical sequence, again tighten bolt 1 through bolt 9.

Torque for bolts … 135 ± 20 N·m (100 ± 15 lb ft)

- In a numerical sequence, again tighten bolt 10 through bolt 24.

Torque for bolts … 55 ± 10 N·m (40 ± 7 lb ft)

(2) The maximum permissible change from an exact vertical face at four points. … 0.38 mm (0.015 inch)

|

|

|

|

|

|

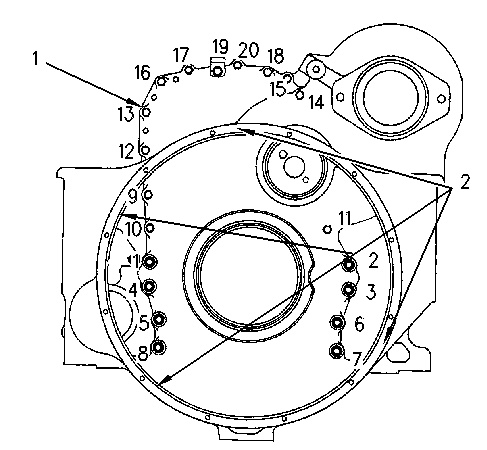

| Illustration 2 | g00383374 |

|

120-9128 Flywheel Housing Group |

|

Note: During assembly, inspect the following components for any foreign materials: the front face of the flywheel housing, the two sides of the flywheel housing gasket and the rear face of the cylinder block. These components must be free of the following substances: oil, fuel, water, gasket adhesive, assembly compounds and any other foreign material. After the flywheel housing is installed, cut the gasket even with the pan rail.

(1) To tighten the flywheel housing bolts, use the procedure that follows:

- In a numerical sequence, tighten bolt 1 through bolt 20.

Torque for bolts … 40 ± 10 N·m (30 ± 7 lb ft)

- In a numerical sequence, again tighten bolt 1 through bolt 8.

Torque for bolts … 135 ± 20 N·m (100 ± 15 lb ft)

- In a numerical sequence, again tighten bolt 9 through bolt 20.

Torque for bolts … 55 ± 10 N·m (40 ± 7 lb ft)

(2) The maximum permissible change from an exact vertical face at four points. … 0.38 mm (0.015 inch)

|

|

|

|

|

|

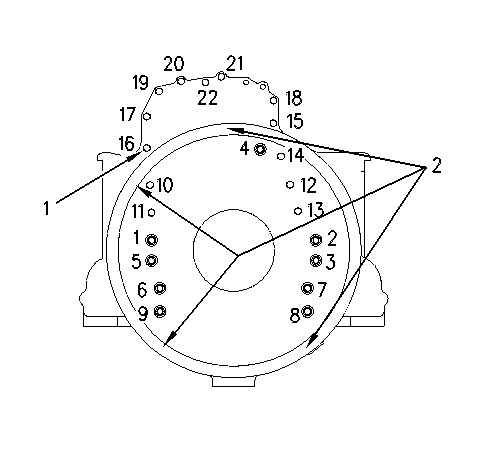

| Illustration 3 | g00383375 |

|

126-3706 Flywheel Housing Group |

|

Note: During assembly, inspect the following components for any foreign materials: the front face of the flywheel housing, the two sides of the flywheel housing gasket and the rear face of the cylinder block. These components must be free of the following substances: oil, fuel, water, gasket adhesive, assembly compounds and any other foreign material. After the flywheel housing is installed, cut the gasket even with the pan rail.

(1) To tighten the flywheel housing bolts, use the procedure that follows:

- In a numerical sequence, tighten bolt 1 through bolt 22.

Torque for bolts … 40 ± 10 N·m (30 ± 7 lb ft)

- In a numerical sequence, again tighten bolt 1 through bolt 9.

Torque for bolts … 135 ± 20 N·m (100 ± 15 lb ft)

- In a numerical sequence, again tighten bolt 10 through bolt 22.

Torque for bolts … 55 ± 10 N·m (40 ± 7 lb ft)

(2) The maximum permissible change from an exact vertical face at four points. … 0.38 mm (0.015 inch)

|

|

|

|

|

|

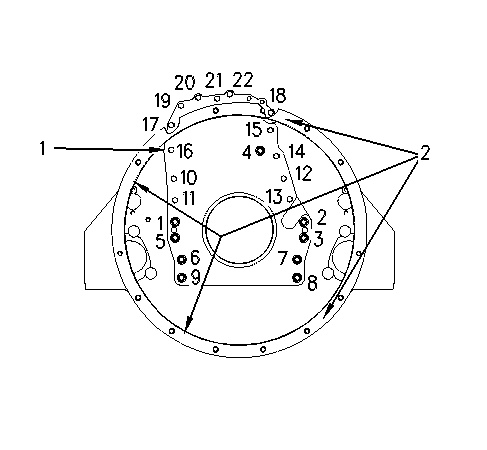

| Illustration 4 | g00383376 |

|

130-4680 Flywheel Housing Group |

|

Note: During assembly, inspect the following components for any foreign materials: the front face of the flywheel housing, the two sides of the flywheel housing gasket and the rear face of the cylinder block. These components must be free of the following substances: oil, fuel, water, gasket adhesive, assembly compounds and any other foreign material. After the flywheel housing is installed, cut the gasket even with the pan rail.

(1) To tighten the flywheel housing bolts, use the procedure that follows:

- In a numerical sequence, tighten bolt 1 through bolt 22.

Torque for bolts … 40 ± 10 N·m (30 ± 7 lb ft)

- In a numerical sequence, again tighten bolt 1 through bolt 9.

Torque for bolts … 135 ± 20 N·m (100 ± 15 lb ft)

- In a numerical sequence, again tighten bolt 10 through bolt 22.

Torque for bolts … 55 ± 10 N·m (40 ± 7 lb ft)

(2) The maximum permissible change from an exact vertical face at four points. … 0.38 mm (0.015 inch)

|

|

|

|

|

|

| Illustration 5 | g00383377 |

|

135-7634 Flywheel Housing Group |

|

Note: During assembly, inspect the following components for any foreign materials: the front face of the flywheel housing, the two sides of the flywheel housing gasket and the rear face of the cylinder block. These components must be free of the following substances: oil, fuel, water, gasket adhesive, assembly compounds and any other foreign material. After the flywheel housing is installed, cut the gasket even with the pan rail.

(1) To tighten the flywheel housing bolts, use the procedure that follows:

- In a numerical sequence, tighten bolt 1 through bolt 24.

Torque for bolts … 40 ± 10 N·m (30 ± 7 lb ft)

- In a numerical sequence, again tighten bolt 1 through bolt 9.

Torque for bolts … 135 ± 20 N·m (100 ± 15 lb ft)

- In a numerical sequence, again tighten bolt 10 through bolt 24.

Torque for bolts … 55 ± 10 N·m (40 ± 7 lb ft)

(2) The maximum permissible change from an exact vertical face at four points. … 0.38 mm (0.015 inch)