|

|

|

|

|

|

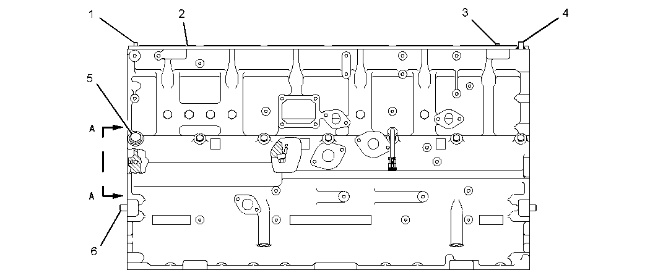

| Illustration 1 | g01097311 |

|

Right side view |

|

(1) Dowel

-

Apply 7M-7456 Bearing Mount Compound to the dowel before installation.

- The dowel extends above the top surface of the cylinder block by the following distance. … 18.5 ± 0.5 mm

(0.73 ± 0.02 inch)

(2) Spacer plate

- Thickness of the spacer plate … 8.585 ± 0.025 mm

(0.3380 ± 0.0010 inch)

- Thickness of the gasket that is placed between the spacer plate and the cylinder block … 0.20 ± 0.02 mm

(0.008 ± 0.001 inch)

- Cylinder liner projection above the spacer plate … 0.025 to 0.152 mm

(0.0010 to 0.0060 inch)

(3) Dowel

- The dowel extends above the top surface of the cylinder block by the following distance. … 16.0 ± 0.5 mm

(0.63 ± 0.02 inch)

(4) Dowel

-

Apply 7M-7456 Bearing Mount Compound to the dowel before installation.

- The dowel extends above the top surface of the cylinder block by the following distance. … 20.0 ± 0.5 mm

(0.79 ± 0.02 inch)

(5) Plug

- Tighten the plug to the following torque. … 70 ± 10 N·m

(52 ± 7 lb ft)

(6) Dowel

- The dowels extend past the end of the cylinder block by the following distance. … 19.1 ± 0.5 mm

(0.75 ± 0.02 inch)

|

|

|

|

|

|

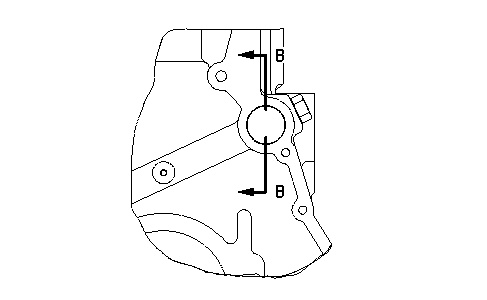

| Illustration 2 | g00284986 |

|

View A-A |

|

|

|

|

|

|

|

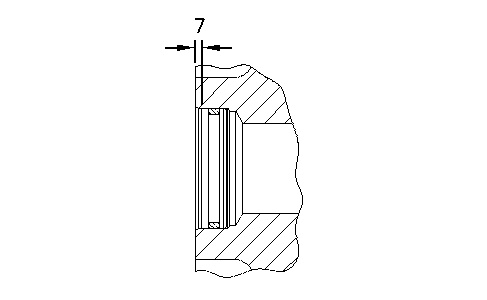

| Illustration 3 | g00562849 |

|

View B-B |

|

(7) Installation depth of the plug … 2.0 ± 2.0 mm

(0.08 ± 0.08 inch)

|

|

|

|

|

|

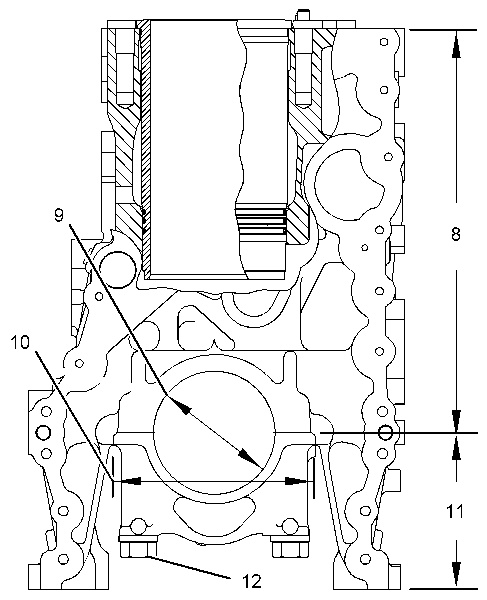

| Illustration 4 | g01096193 |

|

Front view |

|

(8) Dimension from the centerline of the crankshaft bearing bore to the top of the cylinder block

- New … 425.45 ± 0.15 mm

(16.750 ± 0.006 inch) - Minimum … 425.02 mm

(16.733 inch)

Note: The total flatness of the top contact surface of the cylinder block must be within 0.10 mm (0.004 inch). The flatness must also be within 0.05 mm (0.002 inch) for any 177.5 mm (6.99 inch) section of the surface.

(9) Bore in the cylinder block for the main bearings … 129.891 ± 0.013 mm (5.1138 ± 0.0005 inch)

(10) Main bearing cap

- Main bearing cap width … 215.900 ± 0.025 mm (8.5000 ± 0.0010 inch)

- Width of the cylinder block for the main bearing cap … 215.900 ± 0.013 mm

(8.5000 ± 0.0005 inch)

(11) New dimension from the centerline of the crankshaft bearing bore to the bottom of the cylinder block pan rails … 165.10 ± 0.10 mm

(6.500 ± 0.004 inch)

(12) Main bearing cap bolts

|

|

|

|

|

|

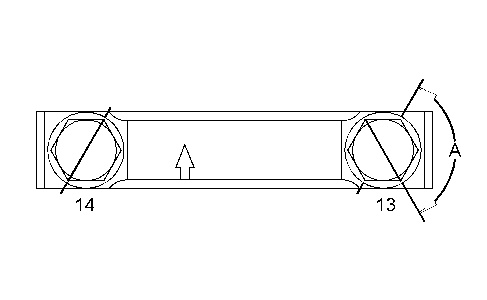

| Illustration 5 | g01062353 |

|

Torque-turn tightening method for main bearing cap bolts |

|

Use the following procedure in order to tighten the main bearing cap bolts:

- Apply clean engine oil to the threads of the bolts.

- Tighten the bolts first on the bearing tab side (13) of the cap.

Torque for bolts … 260 ± 14 N·m

(190 ± 10 lb ft)

- Tighten the bolts on the opposite end (14) of the cap.

Torque for bolts … 260 ± 14 N·m

(190 ± 10 lb ft)

- Put a mark on each bolt and each cap.

- Tighten the bolts on the opposite end of the bearing tab (14) from the mark to angle (A) .

Angle (A) … 120 ± 5 degrees (2 flats)

- Tighten the bolts on the bearing tab side (13) of the cap from the mark to the following value.

Angle (A) … 120 ± 5 degrees (2 flats)

|

|

|

|

|

|

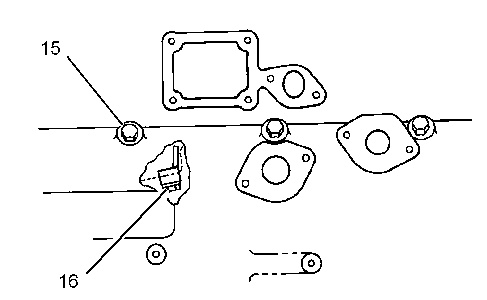

| Illustration 6 | g01096201 |

|

Right side view |

|

(15) Straight thread O-ring plug

(16) Piston cooling jet

-

To prevent damage to the piston cooling jets during service, the piston cooling jets must be removed.

- Minimum permissible clearance between the piston, the piston cooling jet, and the crankshaft … 0.63 mm

(0.025 inch)

|

|

|

|

|

|

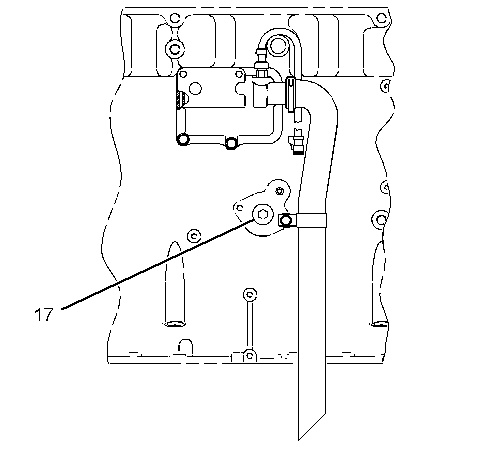

| Illustration 7 | g01097309 |

|

Left side view |

|

(17) Plug

- Tighten the plug to the following torque. … 35 ± 7 N·m (25 ± 5 lb ft)