Remove & Install Valve Springs

*Part of 9U-7241 Valve Spring Compressor Group.

Start By:

a. remove rocker arm and shaft assemblies

b. remove electronic unit injectors

NOTE: The valve spring assemblies can be removed with the cylinder head either on or off the cylinder block. The procedure which follows is for removing and installing the cylinder head valve springs with the cylinder head attached to the cylinder block. Make sure the piston for the valve spring assembly being removed is positioned at the top of the compression stroke (TC) before removing any components. Failure to properly position the piston will allow the valves to fall into the cylinder liner. If a valve falls into the cylinder liner, the cylinder head must be removed.

1. Position the piston for the valve spring assembly being removed at the top of the compression stroke (TC).

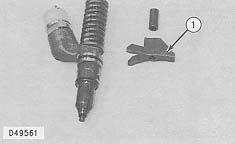

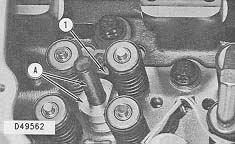

NOTE: Use hold down clamp (1) from the electronic unit injector to secure Tooling (A) to the cylinder head.

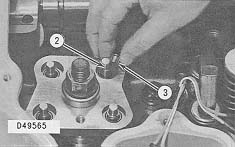

2. Install the stud and base of Tooling (A) into the injector sleeve bore as shown. Use clamp (1) and the bolt from Tooling (A) to secure the stud and base assembly to the cylinder head.

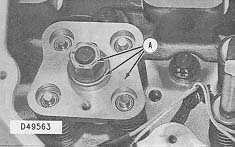

Install the plate, thrust bearing, washer and nut of Tooling (A).

3. Install the remainder of Tooling (A) as shown.

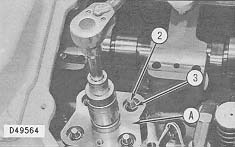

4. Tighten the nut on Tooling (A) until locks (3) are loose on valves (2).

5. Remove two locks (3) from each valve (2).

6. Slowly loosen and remove the nut, washer, thrust bearing and plate from Tooling (A).

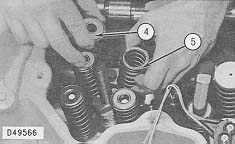

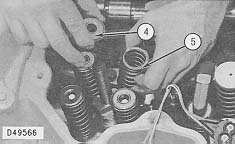

7. Remove rotocoils (4), valve springs (5) and washers (6) from each valve (2).

8. Use Tool (B) to check the valve springs (spring force). See the Specifications Module, for necessary information.

9. Repeat Steps 1 through 8 for the remaining valve spring assemblies needing removed.

NOTE: The following steps are for installing the valve spring assemblies.

10. Put clean engine oil on the valve stem.

11. Install washer (6), valve spring (5) and rotocoil (4) on each valve (2).

12. Use Tooling (A) to compress valve spring (5).

NOTE: Locks (3) are tapered. When installing locks (3) the large (thick) diameter should face up.

13. Install two locks (3) on each valve (2).

|

Locks (3) can be thrown from the valve stem when removing Tool (A). To avoid possible personal injury, make sure locks (3) are seated in their correct position on valve (2). |

14. Slowly loosen and remove the nut from Tooling (A). Make sure locks (3) stay positioned.

15. Hit each valve (2) with a soft hammer to seat locks (3).

End By:

a. install electronic unit injectors

b. install rocker arm and shaft assemblies