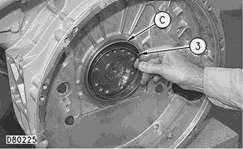

Remove Crankshaft Rear Seal & Wear Sleeve

Start By:

a. remove flywheel

|

|

| NOTICE |

|---|

|

Any time the crankshaft rear seal is removed from the wear sleeve, a new crankshaft rear seal and wear sleeve must be installed as a unit. If the crankshaft rear seal is put back on the wear sleeve, the crankshaft rear seal will be damaged. |

|

|

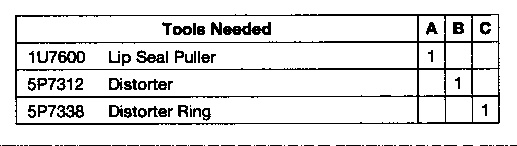

1. Drill three (3/16 in) holes in crankshaft rear seal (1) approximately 120 degreesapart.

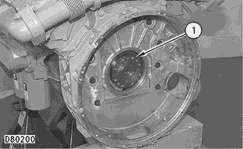

2. Remove crankshaft rear seal (1) from flywheel housing (2) with Tooling (A).

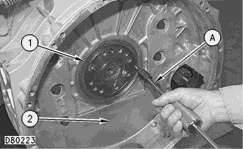

3. Install Tool (C) in the rear seal bore of flywheel housing (2).

4. Install Tool (B) between Tool (C) and the wear sleeve. Turn Tool (B) until the edge of the tool makes a flat place (crease) in the wear sleeve. Do this in two or more places until the wear sleeve is loose.

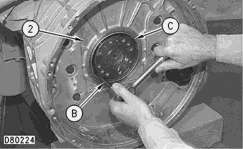

5. Remove Tool (C) and wear sleeve (3) by hand.

Install Crankshaft Rear Seal & Wear Sleeve

|

|

| NOTICE |

|---|

|

The crankshaft rear seal and wear sleeve come as a set and must not be separated from each other at any time. Carefully read Special Instruction, SMHS8508, that is included with each crankshaft rear seal and wear sleeve before any handling of the crankshaft rear seal group is made. |

|

|

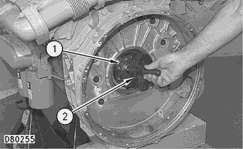

1. Clean and prepare the outside diameter of crankshaft (1) with 4C-9500 Quick Cure Primer. Apply 4C-9507 Retaining Compoundto the crankshaft outside diameter.

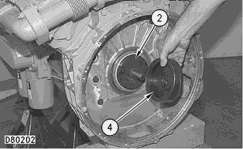

2. Install locator (2) and the bolts on the rear of crankshaft (1).

3. Put wear sleeve and crankshaft rear seal (3) as a unit on locator (2) with the lip of the crankshaft rear seal toward the front of the engine.

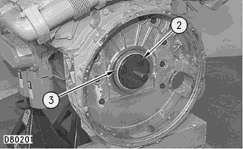

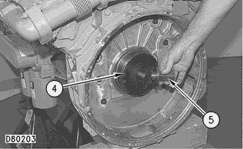

4. Put installer (4) in position over locator (2).

5. Put clean engine oil on the face of nut (5), and install it on the locator. Tighten the nut until installer (4) bottoms out.

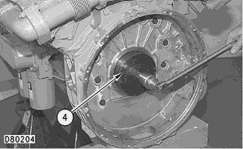

6. Remove Tooling (A), and check crankshaft rear seal and wear sleeve (3) for the correct position after installation.

End By:

a. install flywheel