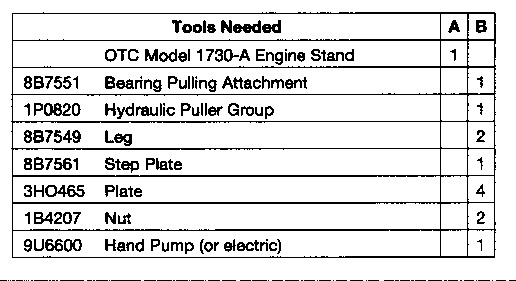

Remove Crankshaft & Gear

Start By:

a. remove flywheel housing

b. remove valve lifters

c. remove pistons and connecting rod assemblies

d. remove timing gear cover and oil pump

1. Fasten a hoist, and put the engine in position on Tool (A).

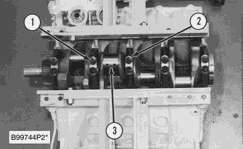

2. Turn crankshaft (3) until the timing mark on the crankshaft gear is in alignment with the timing mark on the camshaft gear.

NOTE: For more detail about removal of main bearings, see the topic, “Remove & Install Crankshaft Main Bearings”.

3. Remove bolts (1) and main bearing caps (2). Remove the lower halves of the main bearings from the caps.

4. Install two of the bolts that hold the flywheel in place in the end of the crankshaft.

|

|

| NOTICE |

|---|

|

Be careful not to damage the crankshaft journals when the crankshaft is removed. |

|

|

5. Fasten a hoist, and remove crankshaft (3) from the engine. The weight of the crankshaft is approximately 54 kg (120 lb).

6. Remove the upper halves of the main bearings from the cylinder block.

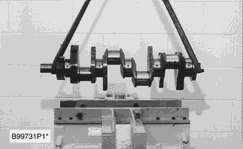

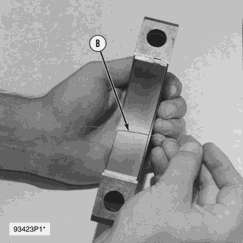

7. Install Tooling (B), and remove the gear from the crankshaft.

Install Crankshaft & Gear

1. Install the key for the crankshaft gear so it is even with the end of the crankshaft.

2. Heat the crankshaft gear to a maximum temperature of 260°C (500°F). Install the gear on the crankshaft with the timing mark on the gear toward the pulley end of the crankshaft.

3. Install the thrust bearing for the No. 4 main.

NOTE: Install the bearings dry when the clearance checks are made. Put clean engine oil on the bearings for final assembly.

4. Install the upper main bearings (the bearings with oil hole) into the engine block.

5. Install two of the bolts that hold the flywheel in place in the end of the crankshaft. Fasten a hoist, and put the crankshaft in position in the block. Make sure the timing mark on the crankshaft gear is in alignment with the timing mark on the camshaft gear.

NOTE: For more details about installation of main bearings, see the topic, “Remove & Install Crankshaft Main Bearings” in this manual.

|

|

| NOTICE |

|---|

|

When the bearing caps are installed, make sure the number on the side of the cap is next to and respective with the number on the engine block. |

|

|

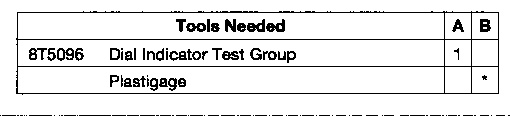

If the crankshaft journals and bores for the block and rods were measured at disassembly and found to be within specifications, no further checks are necessary. However, if the serviceman still wants to measure the bearing clearances, Plastigage is recommended. Lead wire, shim stock or use of a dial bore gauge can damage the bearing surface.

The serviceman must be very careful to use Plastigage correctly. The following points must be remembered.

…Make sure that the backs of the bearings and the bores are clean and dry.

…Make sure that the bearing locking tabs are properly seated in their slots.

…The crankshaft must be free of oil where the Plastigage touches it.

…If the main bearing clearances are checked with the engine upright or on its side, the crankshaft must be supported. Use a jack under an adjacent crankshaft counterweight, and hold the crankshaft against the crown of the bearing. If the crankshaft is not supported, the weight of the crankshaft will cause incorrect readings.

…Put a piece of Plastigage on the crown of the bearing half that is in the cap. Do notallow the Plastigage to extend over the edge of the bearing.

…Install the bearing cap using the correct torque-turn specifications. Do notuse an impact wrench. Be careful not to dislodge the bearing when the cap is installed.

… Do notturn the crankshaft with the Plastigage installed.

…Carefully remove the cap but do notremove the Plastigage. Measure the width of the Plastigage when it is in the bearing cap or on the crankshaft journal. Do this by using the correct scale on the package. Record the measurements.

…Remove the Plastigage before reinstalling the cap.

When using Plastigage, the readings can sometimes be unclear. For example, all parts of the Plastigage are not the same width. Measure the major widths to make sure that they are within the specification range. Also, experience has shown that when checking clearances tighter than 0.10 mm (.004 in)the readings may be low by 0.013 to 0.025 mm (.0005 to .0010 in). Out-of-round journals can give faulty readings. Also, journal taper may be indicated when one end of the Plastigage is wider than the other.

NOTE: When the bearing clearance is checked and the engine is in a vertical position, the crankshaft will have to be lifted up with a force equal to the weight of the crankshaft and held against the upper halves of the main bearings to get a correct measurement with Plastigage. The Plastigage will not hold the weight of the crankshaft and give a correct indication. If the engine is in a horizontal position, such as on an engine stand, it is not necessary to hold the crankshaft up.

Do not turn crankshaft when Plastigage is in position to check clearance.

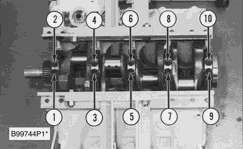

6. Check the bearing clearance with Plastigage (B). Put the lower main bearings into the caps. Put the caps in position, and install the bolts. Tighten the bolts in number sequence as follows:

a. Tighten bolts 1 through 10 to a torque of 40 ± 4 N·m (30 ± 3 lb ft).

|

|

| NOTICE |

|---|

|

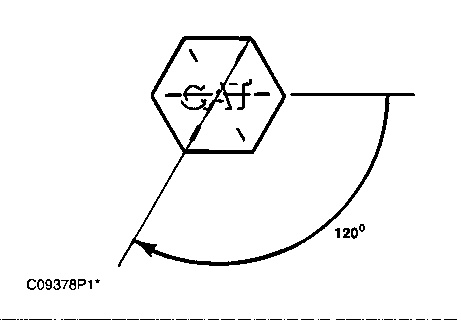

Do not use an impact wrench to tighten the nuts the additional 120 ± 5 degrees(1/3 turn). |

|

|

b. Put a mark on each bolt head and bearing cap. Tighten bolts 1 through 10 120 ± 5 degrees(1/3 turn) more.

7. Remove the bearing caps, and measure the thickness of the Plastigage. The main bearing clearance must be 0.076 to 0.168 mm (.0030 to .0066 in). The maximum permissible clearance is 0.18 mm (.007 in).

8. Put Clean Engine Oilon the bolt threads and washer faces. Put clean engine oil on the main bearings. Put the bearing caps in position, and install the bolts. Tighten the bolts in number sequence as follows:

a. Tighten bolts 1 through 10 to a torque of 40 ± 4 N·m (30 ± 3 lb ft).

b. Put a mark on each bolt head and bearing cap. Tighten bolts 1 through 10 120 ± 5 degrees(1/3 turn) more.

9. Install indicator group (A), and check the end play of the crankshaft. The end play is controlled by the thrust bearing on No. 4 main bearing. The end play with new bearings must be 0.08 ± 0.25 mm (.003 to .010 in). The maximum permissible end play with a used bearing is 0.36 mm (.014 in).

End By:

a. install timing gear cover and oil pump

b. install pistons and connecting rod assemblies

c. install valve lifters

d. install flywheel housing