Remove Water Separator

Fluid Spillage Containment

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the machine. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to “Tools And Shop Products Guide”, NENG2500 for tools and supplies suitable to collect and contain fluids in Caterpillar machines. Dispose fluids according to local regulations and mandates.

|

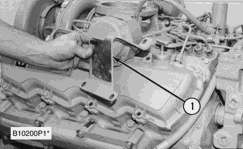

Element (2) is free to fall when clamp (1) is released. |

1. Remove clamp (1) and element (2).

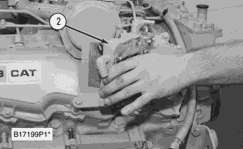

2. Disconnect line (4) from the water separator base.

3. Remove the two nuts and water separator base (3).

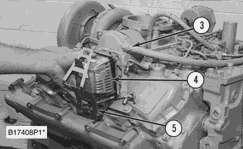

4. Remove three bolts (6), bracket (5) and the spacers.

Install Water Separator

1. Put bracket (1) and the three spacers in position. Install the three bolts. Tighten the bolts to a torque of 14 ± 3 N·m (10 ± 2 lb ft).

2. Put base (2) in position, and install the nuts.

3. Connect line (3) to the base.

4. Put element (4) in position, and install clamp (5).

NOTE: Make sure clamp (5) is tight because element (4) is free to fall.