Troubleshooting

Troubleshooting can be difficult. On the following pages there is a list of possible problems. To make a repair to a problem, make reference to the cause and correction.

This list of problems, causes and corrections will only give an indication of where a possible problem can be, and what repairs are needed. Normally, more of other repair work is needed beyond the recommendations in the list. Remember that a problem is not normally caused only by one part, but by the relation of one part with other parts. This list can not give all possible problems and corrections. The serviceman must find the problem and its source, then make the necessary repairs.

- 1. Contactor Switch for Water Temperature fails to Activate Shutoff.

- 2. Contactor Switch for Water Temperature Activates Shutoff at Wrong Temperature.

- 3. Switch for Oil Pressure Fails to Activate Shutoff.

- 4. Engine Protection Panel Will Not Activate Engine Shutoff.

- 5. Engine Protection Panel Stops Engine When Reset Button is Released.

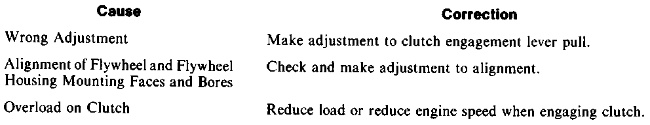

- 6. Clutch Will Not Engage (Slips), Heats or Lever Moves to Released Position.

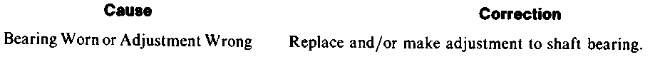

- 7. Clutch Shaft Has Too Much End Play.

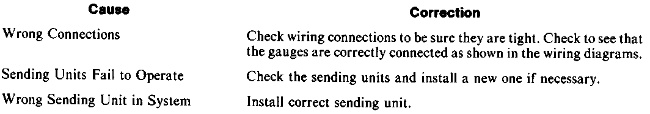

- 8. Electrical Gauges Give Wrong Readings.

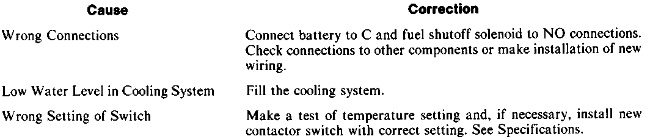

Contactor Switch For Water Temperature Fails To Activate Shutoff

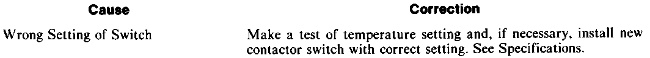

Contactor Switch For Water Temperature Activates Shutoff At Wrong Temperature

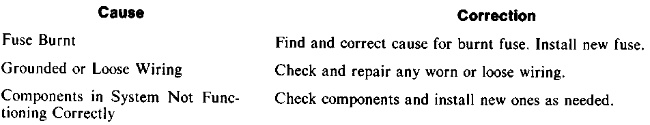

Switch For Oil Pressure Fails To Activate Shutoff

Engine Protection Panel Will Not Activate Engine Shutoff

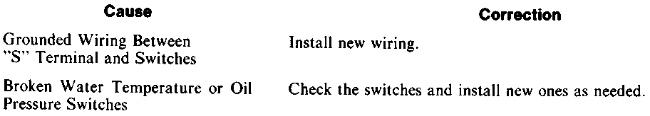

Engine Protection Panel Stops Engine When Reset Button Is Released

Clutch Will Not Engage (Slips), Or Lever Moves To Released Position

Clutch Shaft Has Too Much End Play

Electrical Gauges Give Wrong Readings

Electrical System

Contactor Switch For Water Temperature

- Fabricated heat sink.2F7112 Thermometer.3J5389 Plug.8S4627 Circuit Tester.

First Method of Checking

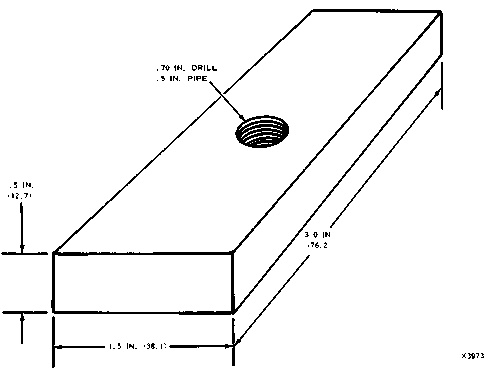

1. Make a heat sink as shown. Material can be brass, steel or cast iron. Drill a 23/32 in. hole through the plate and use a tap to make 1/2 in. NPT threads.

2. Put marks on wire connections to contactor terminals and disconnect wire.

HEAT SINK [Dimensions in inches (mm)]

TEST OF CONTACTOR SWITCH

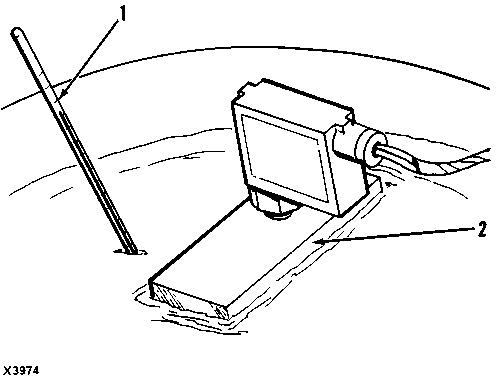

1. 2F7112 Thermometer. 2. Fabricated heat sink.

3. Remove the contactor and install a 3J5389 Plug. Install the contactor switch in the heat sink.

4. Connect the wires to the contactor switch to check all of the system; contactor switch, wires, etc.

NOTE: If the wires can not be disconnected, use the second method of testing.

5. When the contactor switch is connected again, start the engine and run it at low idle rpm. The pressure switch will complete the circuit when the engine is running.

NOTE: When applying heat to the water in Step 6, be sure to stir (keep water moving) while heating.

6. Put the heat sink and contactor element in water. Use blocks to support the heat sink at surface level. Use a torch to make the water hot and read the temperature on thermometer (1) at which the engine stops (switch is closed). For the 5L6435 Contactor, the temperature should be 209 ± 1 ° F (98 ± 0.6 ° C). Let the water temperature go down. The contactor switch will open when the temperature is 12 ° F (8 ° C) lower than the temperature at which the contactor closes.

7. Install new contactor switch if necessary.

To check other components in the system, put a jumper wire between C and NO terminals of the contactor switch for water temperature.