Grounding Practices

Proper grounding for the machine electrical system and the engine electrical system is necessary for proper machine performance and reliability. Improper grounding will result in uncontrolled electrical circuit paths and unreliable electrical circuit paths.

Uncontrolled engine electrical circuit paths can result in damage to main bearings, crankshaft bearing journal surfaces, and aluminum components.

To ensure proper functioning of the machine and engine electrical systems, an engine-to-frame ground strap with a direct path to the negative battery post must be used. This may be provided by way of a starting motor ground, a frame to starting motor ground, or a direct frame to engine ground.

An engine-to-frame ground strap must be used in order to connect the grounding stud of the engine to the frame of the vehicle and to the negative battery post.

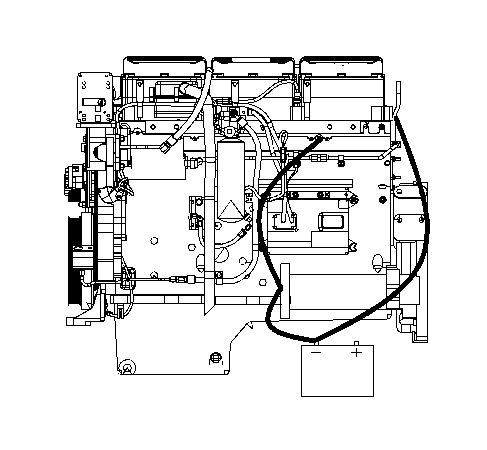

|

|

|

|

|

|

| Illustration 1 | g01028488 |

|

Typical example Grounding Stud To Battery Ground (“-“) |

|

|

|

|

|

|

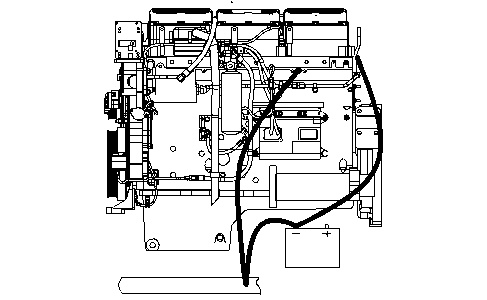

|

| Illustration 2 | g01028479 |

|

Typical example Alternate grounding stud to battery ground (“-“) |

|

The engine must have a wire ground to the battery.

Ground wires or ground straps should be combined at ground studs that are only for ground use. All of the grounds should be tight and free of corrosion.

All of the ground paths must be capable of carrying any likely current faults. An AWG #0 or larger wire is recommended for the grounding strap to the cylinder head.

The engine alternator should be battery ground with a wire size that is capable of managing the full charging current of the alternator.

|

|

| NOTICE |

|---|

|

When boost starting an engine, the instructions in Systems Operation, “Engine Starting” should be followed in order to properly start the engine. This engine may be equipped with a 12 volt starting system or a 24 volt starting system. Only equal voltage for boost starting should be used. The use of a higher voltage will damage the electrical system. The Electronic Control Module (ECM) must be disconnected at the “J1/P1” and “J2/P2” locations before welding on the vehicle. |

|

|

The engine has several input components which are electronic. These components require an operating voltage.

Unlike many electronic systems of the past, this engine is tolerant to common external sources of electrical noise. Buzzers that use electrical energy can cause disruptions in the power supply. If buzzers are used anywhere on the machine, the engine electronics should be powered directly from the battery system through a dedicated relay. The engine electronics should not be powered through a common power source with other activities that are related to the keyswitch.

Engine Electrical System

The electrical system has the following separate circuits:

- Charging

- Starting (If equipped)

- Accessories with low amperage

Some of the electrical system components are used in more than one circuit. The following components are common in more than one circuit:

- Battery or batteries

- Circuit breakers

- Battery cables

- Ammeter

The charging circuit is in operation when the engine is running. An alternator makes electricity for the charging circuit. A voltage regulator in the circuit controls the electrical output in order to keep the battery at full charge.

The starting circuit is activated only when the start switch is activated.

The accessory circuit with the low amperage and the charging circuit are connected through the ammeter. The starting circuit is not connected through the ammeter.

Charging System Components

Alternator

The alternator is driven by a belt from the crankshaft pulley. This alternator is a three-phase, self-rectifying charging unit, and the regulator is part of the alternator.

The alternator design has no need for slip rings and the only part that has movement is the rotor assembly. All conductors that carry current are stationary. The following conductors are in the circuit:

- Field winding

- Stator windings

- Six rectifying diodes

- Regulator circuit components

The rotor assembly has many magnetic poles that look like fingers with air space between each of the opposite poles. The poles have residual magnetism. The residual magnetism produces a small magnetic field between the poles. As the rotor assembly begins to turn between the field winding and the stator windings, a small amount of alternating current (AC) is produced. The AC current is produced in the stator windings from the small magnetic field. The AC current is changed to direct current (DC) when the AC current passes through the diodes of the rectifier bridge. The current is used for the following applications:

- Charging the battery

- Supplying the accessory circuit that has the low amperage

- Strengthening the magnetic field

The first two applications use the majority of the current. As the DC current increases through the field windings, the strength of the magnetic field is increased. As the magnetic field becomes stronger, more AC current is produced in the stator windings. The increased speed of the rotor assembly also increases the current and voltage output of the alternator.

The voltage regulator is a solid-state electronic switch. The voltage regulator senses the voltage in the system. The voltage regulator switches ON and OFF many times per second in order to control the field current for the alternator. The alternator uses the field current in order to generate the required voltage output.

|

|

| NOTICE |

|---|

|

Never operate the alternator without the battery in the circuit. Making or breaking an alternator connection with heavy load on the circuit can cause damage to the regulator. |

|

|

|

|

|

|

|

|

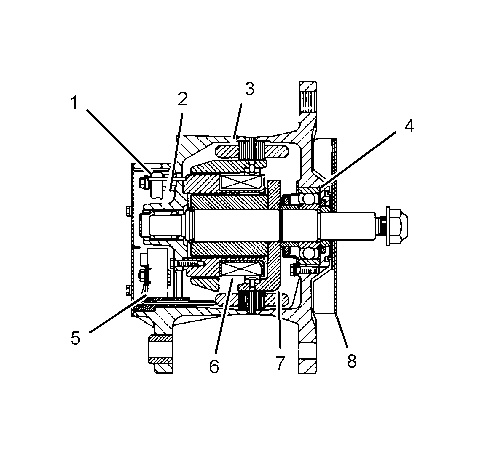

| Illustration 3 | g01241796 |

|

Typical alternator components (1) Regulator (2) Roller bearing (3) Stator winding (4) Ball bearing (5) Rectifier bridge (6) Field winding (7) Rotor assembly (8) Fan |

|

Starting System Components

Starting Solenoid

|

|

|

|

|

|

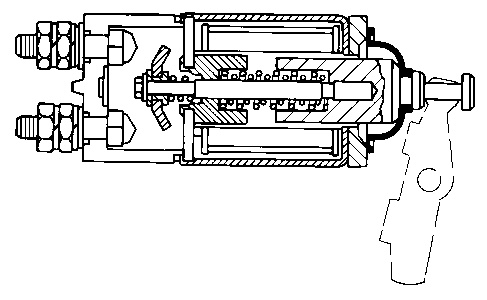

| Illustration 4 | g00317613 |

|

Typical starting solenoid |

|

|

|

|

|

|

|

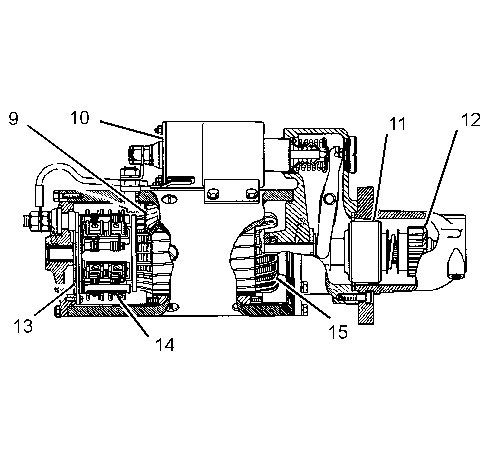

| Illustration 5 | g01241797 |

|

Typical starting motor components (9) Field (10) Solenoid (11) Clutch (12) Pinion (13) Commutator (14) Brush assembly (15) Armature |

|

The starting solenoid (10) is an electromagnetic switch that performs the following basic operations:

- The starting solenoid (10) closes the high current starting motor circuit with a low current start switch circuit.

- The starting solenoid (10) engages the pinion for the starting motor (4) with the ring gear.

Solenoid (10) has windings (one or two sets) around a hollow cylinder. A plunger with spring pressure(core) is inside of the cylinder. The plunger can move forward and backward. When the start switch is closed and electricity is sent through the windings, a magnetic field (9) is made. The magnetic field (9) pulls the plunger forward in the cylinder. This moves the shift lever in order to engage the pinion drive gear with the ring gear. The front end of the plunger then makes contact across the battery and motor terminals of solenoid (10) . Next, the starting motor begins to turn the flywheel of the engine.

When the start switch is opened, current no longer flows through the windings. The spring now pushes the plunger back to the original position. At the same time, the spring moves the pinion gear away from the flywheel.

When two sets of solenoid windings are used, the windings are called the hold-in winding and the pull-in winding. Both sets of windings have the same number of turns around the cylinder, but the pull-in winding uses a wire with a larger diameter. The wire with a larger diameter produces a greater magnetic field (9) . When the start switch is closed, part of the current flows from the battery through the hold-in windings. The rest of the current flows through the pull-in windings to the motor terminal. The current then flows through the motor to ground. Solenoid (10) is fully activated when the connection across the battery and the motor terminal is complete. When solenoid (10) is fully activated, the current is shut off through the pull-in windings. At this point, only the smaller hold-in windings are in operation. The hold-in windings operate for the duration of time that is required in order to start the engine. Solenoid (10) will now draw less current from the battery, and the heat that is generated by solenoid (10) will be kept at an acceptable level.