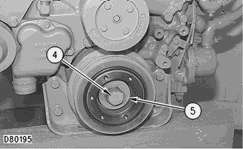

Remove Crankshaft Pulley

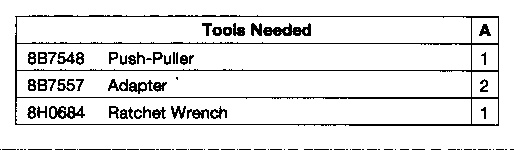

1. Loosen the tension on the vee belts, and remove vee belts (1) from the crankshaft pulley.

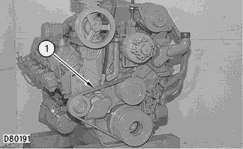

2. Remove bolts (2). Remove pulley adapter (3).

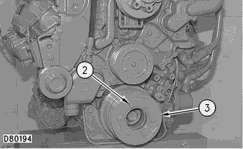

3. Remove bolt (4) and washer (5) from the crankshaft.

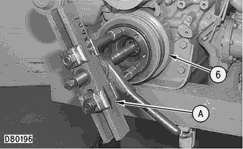

4. Use Tooling (A) to pull crankshaft pulley (6) from the crankshaft.

Install Crankshaft Pulley

1. Put clean engine oil on the lip of the front crankshaft seal and seal surface of the crankshaft pulley.

2. Put crankshaft pulley (6) in position on the end of the crankshaft.

|

|

| NOTICE |

|---|

|

Bolt (4) and washer (5) must not be used to install pulley (1) on the crankshaft. |

|

|

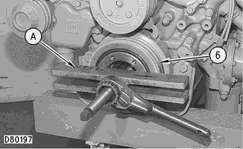

3. Install the screw of Tooling (A) in the end of the crankshaft. Put the crossbar of Tooling (A) on the screw and against the pulley. Use Tooling (A) to push the pulley on to the crankshaft until it makes contact with the crankshaft gear inside the timing gear housing. Remove Tooling (A).

4. Install washer (5) and bolt (4) in the end of the crankshaft. Tighten the bolt to a torque of 624 ± 80 N·m (460 ± 60 lb ft).

NOTE: When a front power take-off is used, increase the torque of

bolt (4) to 950 ± 50 N·m (700 ± 37 lb ft).

5. Put pulley adapter (3) in position and install bolts (2). Tighten bolts (2) to a torque of 55 ± 7 N·m (41 ± 5 lb ft).

6. Install vee belts (1), and make an adjustment to the belt tension. See the topic “Belt Tension Chart” in the Specifications Manual.